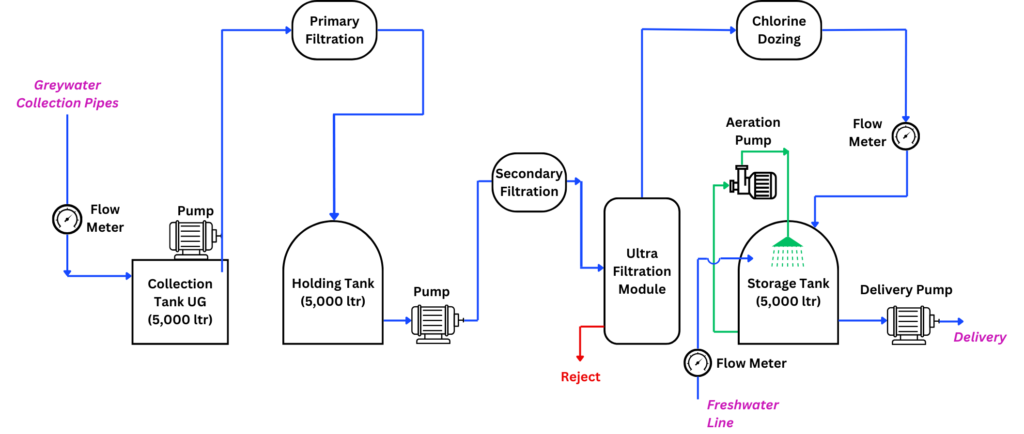

GREYWATER TREATMENT PROCESS

Our on-site greywater treatment solution involves capturing greywater from showers, hand basins and laundry, treating and reusing it for applications such as flushing of toilets, gardening/landscaping, construction, etc.

Our recycling solution largely comprises of physical and chemical treatment of greywater. The treatment can be classified into following processes:

- Coagulation

- Filtration

- Chemical treatment

- Aeration

Basics of the Process

Coagulation

Coagulation and flocculation refer to settling of heavy solids in the raw greywater at the bottom of the tank through mixing a metered quantity of coagulant. This process reduces the suspended solids in the greywater by approximately 80%.

Filtration

A 3-level filtration for removing 99% suspended solids as well as certain dissolved solids. Our filters comprise of basket strainers, micro-filters and ultra-filtration elements.

Disinfection

Disinfection process involves dozing the filtered water with pre-determined quantity of liquid chemical(s) for fully removing bacterial contents and pathogens.

Aeration

Aeration involves periodic infusion of air into the filtered and disinfected water. Aeration keeps the Biological Oxygen Demand (BOD) of water from rising and prevents generation of foul odour and decomposition of water.

Details

Basic Filtration

We utilise a series of filters for capturing and removing most suspended particles (such as dirt, hair, skin and other solids). The primary filter acts as a strainer which removes coarse particles. We also use a polypropylene filter as a secondary filter which captures particles of size of up to 30 microns (0.03 mm).

Ultra Filtration

Ultra filtration is a process of passing the feed water through a hollow fibre membrane using a feeder pump. The hollow fibre membrane captures all suspended particles to the size of 0.02 microns. This ensures that 99% of the suspended solids as well as bacteria and viruses are removed from the treated water after ultrafiltration.

Chlorination

This process kills any leftover micro-organisms such as bacteria present in the treated water and makes the water safe for storage and reuse. Chlorine is the most commonly used disinfectant for sterilizing greywater. A typical dosage for effective disinfection is 10 mg of chlorine for every litre of greywater.

Aeration

Aeration refers to constant circulation of air through the greywater stored in the primary storage tank. Aeration plays a key role in ensuring that COD/BOD of processed greywater doesn’t rise causing a breakdown in water quality. Aeration is achieved through an air pump and a network of pipes which constantly circulate fresh air through the water.

Layout of a typical 15 KLD greywater treatment plant is described below. Contact us for information regarding customization.